2020 High quality Clay Ceramsite - Absorbent ceramsite factories Ceramsite for insulation filter – Huabang

2020 High quality Clay Ceramsite - Absorbent ceramsite factories Ceramsite for insulation filter – Huabang Detail:

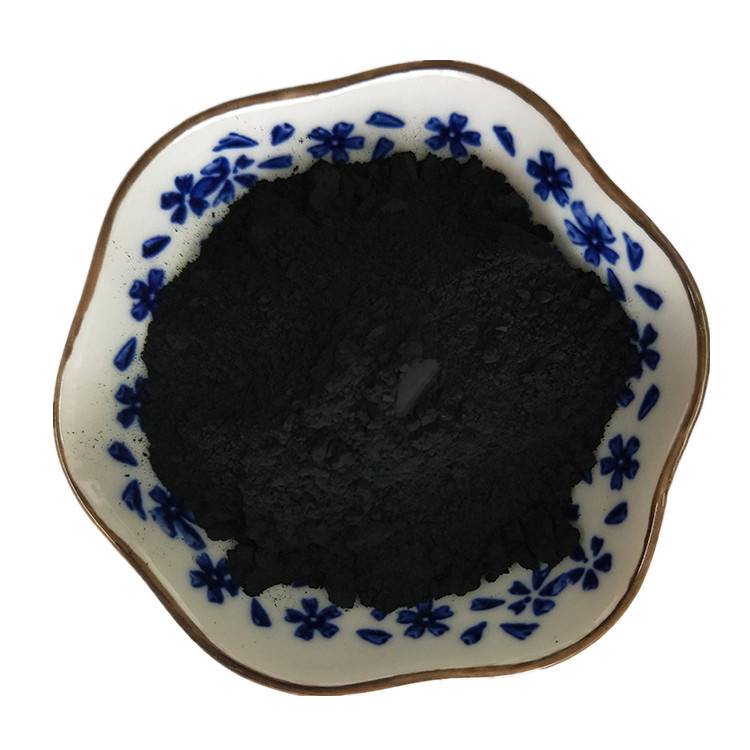

Ceramsite is a kind of light aggregate produced by foaming in rotary kiln. It has spherical shape, smooth and hard surface, honeycomb inside, low density, low thermal conductivity and high strength. In refractory industry, ceramsite is mainly used as the aggregate of thermal insulation refractory.

The bulk density of ceramsite itself is less than 1100kg / m3, generally 300-900kg / m3. The density of concrete made of ceramsite is 1100-1800kg / m3, and the corresponding compressive strength of concrete is 30.5-40.0mpa. The biggest characteristic of ceramsite is that it is hard on the outside and has many micro holes in the inside.

High purity Ceramsite Filter Media is a hard and rough in surface, porous inside the structure, and have the advantages of high mechanical strength,large specific surface area and porosity.When it was used in water treatment, Ceramsite Sand filters behave as an activated surface property,a great amount of pollutant entrapment,less water head loss in the filter bed,lower consumption of back-flush water,stable in chemical and gbiologic property,and long service life. Ceramsite Sand filters is a new and efficient filter material to increase the water yield,upgrade the water quality,and save chemicals and energy.

Performance

Thermal insulation: The ceramsite provided by Chinese ceramsite has good heat preservation and insulation because of its porous interior.

Excellent fire resistance: Ordinary flyash ceramsite concrete or flyash ceramsite block integrates heat preservation, earthquake resistance, frost resistance, fire resistance and other properties, especially the fire resistance is more than 4 times that of ordinary concrete.

Good earthquake resistance: Ceramsite concrete has good seismic performance because of its light weight, low elastic modulus and good deformation resistance.

Alkali resistance: Ceramsite concrete not only has better corrosion resistance (acid, alkali) than ordinary concrete. Moreover, it has excellent alkali resistant aggregate reaction ability.

Strong adaptability

Ceramsite Specifications

| Product Type | LECA/Ceramsite/Clay Ball |

| Material | Clay/Shale |

| Density | 350-1700kg/CBM |

| Size | 0-4mm/4-8mm/8-12mm/12-16mm/16-25mm |

| Feature | Good filtration,lighter density,various size,high strength |

| Color | Red/Crimson/Gray |

| Packaging | Woven bag or as customer designed |

Product detail pictures:

Related Product Guide:

We have been committed to offering easy,time-saving and money-saving one-stop purchasing service of consumer for 2020 High quality Clay Ceramsite - Absorbent ceramsite factories Ceramsite for insulation filter – Huabang , The product will supply to all over the world, such as: Cancun, Colombia, Amsterdam, We integrate all our advantages to continuously innovate, improve and optimize our industrial structure and product performance. We will always believe in and work on it. Welcome to join us to promote green light, together we will make a better Future!

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!